Exploring the Benefits of SCR Catalyst Cummins for Heavy-Duty Diesel Engines

The use of an SCR (Selective Catalytic Reduction) catalyst in heavy-duty diesel Cummins engines has become increasingly popular in recent years. This technology is designed to reduce emissions of nitrogen oxides (NOx), a major contributor to air pollution, while also improving fuel economy and engine performance. In this article, we will explore the benefits of SCR catalysts for heavy-duty diesel engines and discuss why they are becoming an increasingly popular choice for many operators.

SCR catalysts work by converting NOx into harmless nitrogen and water vapor through a chemical reaction with ammonia or urea. This process is highly efficient, reducing NOx emissions by up to 90%. Additionally, the use of SCR catalysts can improve fuel economy by up to 5%, as well as reduce maintenance costs (especially when you take into account the Cummins engine oil changes) due to fewer deposits on engine components.

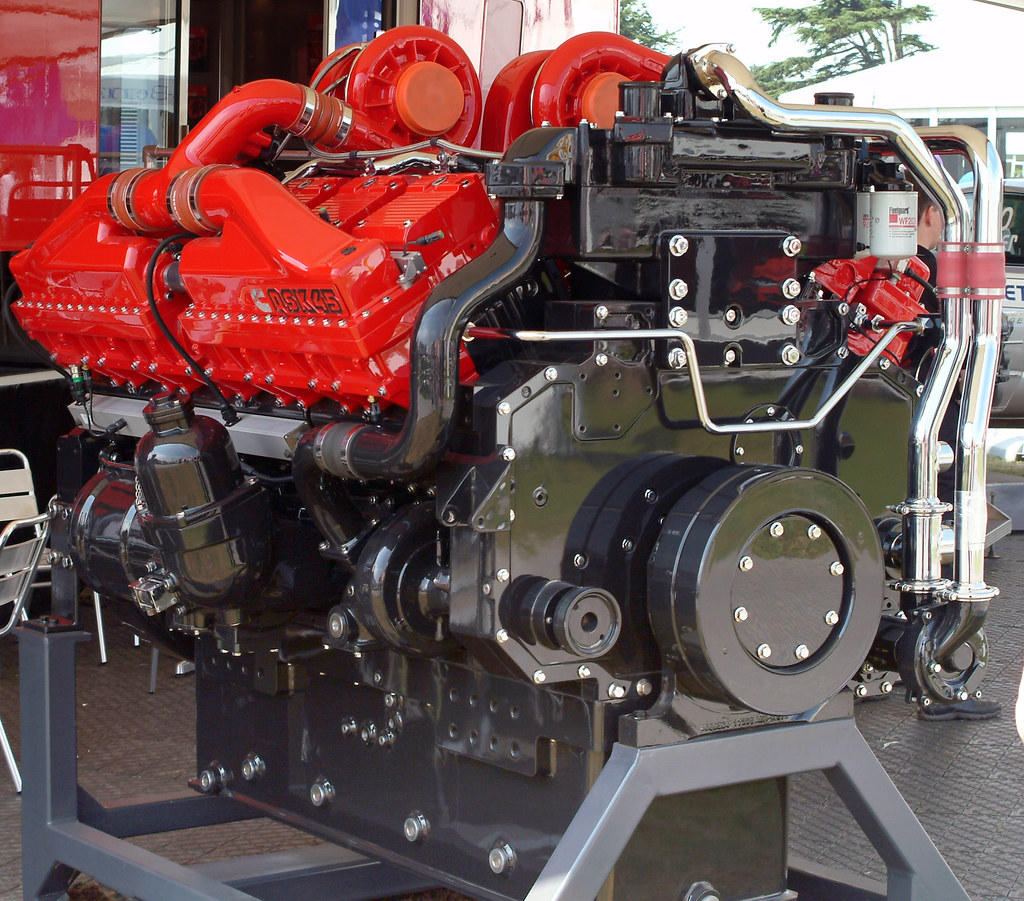

The Cummins brand is one of the leading manufacturers of SCR catalyst systems for heavy-duty diesel engines. Their systems are designed with advanced features such as active regeneration technology that helps keep the catalyst clean and functioning properly over time. Additionally, their systems are designed with robust materials that can withstand extreme temperatures and harsh operating conditions without compromising performance or reliability.

Overall, the use of SCR catalyst systems from Cummins provides numerous benefits for operators who rely on heavy-duty diesel engines in their operations. Not only do these systems help reduce emissions while improving fuel economy and engine performance, but they also provide long-term reliability due to their robust construction and advanced features such as active regeneration technology. As such, it’s no surprise that more operators are turning towards Cummins’ SCR catalyst solutions when looking for ways to improve their operations’ efficiency and sustainability goals.

How SCR Catalyst Cummins Technology is Reducing Emissions in the Transportation Industry

The transportation industry is a major contributor to global emissions, and Cummins has been at the forefront of developing technologies to reduce these emissions. Cummins’ Selective Catalytic Reduction (SCR) catalyst technology is one such innovation that has been instrumental in reducing emissions from diesel engines.

SCR catalysts are designed to convert nitrogen oxides (NOx) into harmless nitrogen and water vapor. This process occurs when a urea-based solution, known as Diesel Exhaust Fluid (DEF), is injected into the exhaust stream of an engine. The DEF reacts with the NOx in the exhaust stream, converting it into harmless nitrogen and water vapor before it exits the tailpipe. This process reduces NOx emissions by up to 90%, making SCR catalysts one of the most effective ways to reduce diesel engine emissions.

Cummins’ SCR catalyst technology has been used in many different applications, including heavy-duty trucks (such as the Nissan 5.0 Cummins diesel engine), buses, construction equipment, marine vessels, and locomotives. By using this technology on these vehicles and machines, Cummins has helped reduce NOx emissions by millions of tons each year worldwide.

In addition to reducing NOx levels in diesel engines, Cummins’ SCR catalyst technology also helps improve fuel economy by up to 5%. This improved fuel efficiency helps lower operating costs for businesses while also reducing their environmental impact at the same time.

Overall, Cummins’ SCR catalyst technology is helping make a significant impact on reducing harmful emissions from diesel engines in the transportation industry worldwide. By utilizing this innovative solution for their vehicles and machines, businesses can help protect our environment while also saving money on fuel costs at the same time.

The Impact of SCR Catalyst Cummins on Fuel Economy and Performance

The introduction of Selective Catalytic Reduction (SCR) catalysts by Cummins has had a significant impact on fuel economy and performance. SCR catalysts are designed to reduce emissions of nitrogen oxides (NOx) from diesel engines, which is an important step in meeting increasingly stringent environmental regulations. In addition to reducing NOx emissions, SCR catalysts also improve fuel economy and performance by allowing the engine to operate more efficiently. This article will discuss the impact of SCR catalyst technology on fuel economy and performance.

SCR catalysts work by converting NOx into harmless nitrogen gas and water vapor through a chemical reaction with urea-based diesel exhaust fluid (DEF). The DEF is injected into the exhaust stream, where it reacts with the NOx molecules to form harmless nitrogen gas and water vapor. This process reduces harmful emissions while also improving engine efficiency due to reduced backpressure in the exhaust system. As a result, engines equipped with SCR catalyst technology can achieve higher levels of power output while consuming less fuel than those without this technology.

In addition to improved engine efficiency, SCR catalyst technology also helps reduce maintenance costs associated with diesel engines due to its ability to reduce soot buildup in the combustion chamber over time. Soot buildup can lead to increased wear on internal components such as pistons and rings, resulting in costly repairs or replacements down the line if not addressed properly. By reducing soot buildup through its chemical reaction with DEF, an SCR catalyst helps extend engine life while reducing maintenance costs for owners over time.

Overall, Cummins’ introduction of Selective Catalytic Reduction (SCR) catalysts has had a positive impact on both fuel economy and performance for diesel engines across multiple industries including automotive, marine, construction equipment, and more. By allowing engines equipped with this technology to operate more efficiently while simultaneously reducing harmful emissions levels through its chemical reaction with DEF injection systems; Cummins’ SCRs have helped make diesel-powered vehicles cleaner burning than ever before while providing improved power output at lower operating costs for owners over time.

Understanding the Cost Savings Associated with SCR Catalyst Cummins Technology

The Selective Catalytic Reduction (SCR) Catalyst Cummins technology is a cost-effective solution for reducing emissions from diesel engines. This technology uses an advanced catalytic converter to reduce the amount of nitrogen oxides (NOx) released into the atmosphere. The SCR Catalyst Cummins system works by injecting a urea-based solution, known as Diesel Exhaust Fluid (DEF), into the exhaust stream. The DEF reacts with NOx in the exhaust and converts it to harmless nitrogen and water vapor, significantly reducing emissions.

The use of SCR Catalyst Cummins technology can result in significant cost savings for businesses that operate diesel engines. By reducing NOx emissions, businesses can avoid costly fines associated with non-compliance with environmental regulations. Additionally, this technology reduces fuel consumption by up to 5%, resulting in lower fuel costs over time. Furthermore, since DEF is relatively inexpensive compared to other fuels, businesses can save money on fuel costs while still meeting their emission reduction goals.

In addition to these direct cost savings associated with using SCR Catalyst Cummins technology, there are also indirect benefits that should be considered when evaluating its value proposition. For example, this technology helps improve air quality which has been linked to improved public health outcomes and increased productivity among workers who are exposed to cleaner air on a daily basis. Additionally, reduced NOx emissions help reduce acid rain which can damage crops and ecosystems over time if left unchecked.

Overall, the use of SCR Catalyst Cummins technology provides numerous benefits that make it an attractive option for businesses looking for ways to reduce their environmental impact while saving money at the same time. By investing in this advanced emission control system now, companies can enjoy long-term cost savings while helping protect our environment for future generations.

Examining the Latest Developments in SCR Catalyst Cummins Technology for Commercial Vehicles

The use of Selective Catalytic Reduction (SCR) technology in commercial vehicles has become increasingly popular in recent years. This technology is designed to reduce emissions from diesel engines, making them more environmentally friendly and compliant with current regulations. Cummins, a leading manufacturer of commercial vehicle engines, has been at the forefront of SCR catalyst development and continues to make advancements in this area. In this article, we will examine the latest developments in SCR catalyst Cummins technology for commercial vehicles.

Cummins’ SCR catalysts are designed to reduce nitrogen oxide (NOx) emissions from diesel engines by up to 90%. The catalysts work by converting NOx into harmless nitrogen and water vapor through a chemical reaction with ammonia or urea-based reductants. The company’s latest generation of SCR catalysts features improved durability and performance compared to earlier models, allowing them to meet even stricter emission standards while providing better fuel economy for operators.

In addition to its standard line of SCR catalysts, Cummins also offers an advanced version called “BlueTech”. This system uses a combination of advanced sensors and software algorithms that allow it to adjust the amount of reductant injected into the exhaust stream based on engine load conditions. This helps ensure that NOx levels remain within acceptable limits while minimizing fuel consumption and reducing operating costs for operators.

Cummins also offers an optional “Active Regeneration” system which can help extend the life of its SCR catalysts by automatically cleaning out soot buildup during periods when the engine is not under heavy load conditions such as idling or low-speed driving. This helps prevent premature failure due to clogging or other issues caused by excessive soot accumulation over time.

Overall, Cummins’ latest developments in SCR catalyst technology have made it easier than ever before for commercial vehicle operators to comply with stringent emission regulations while still enjoying improved fuel economy and reduced operating costs thanks to their advanced systems design features such as BlueTech and Active Regeneration systems. With these advancements continuing into the future, Cummins remains at the forefront when it comes to providing reliable solutions for reducing emissions from diesel engines used in commercial vehicles today (such as the new 6.7 Cummins diesel engine).